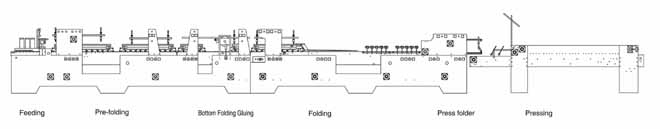

The machine is adopted with strengthened single-side driving system, for steady running and easy maintenance.

The motor is adopted with frequency conversion controller, automatic timing and power saving.

It is adopted double face tooth rod adjusting in operation with shaking motor, ensuring continuous, exact and automatic feeding.

Delivery is adopted with several thick belts cooperation with shaking motor, ensuring continuous, exact and automatic feeding.

It is adopted the grinding equipment, which makes the glue more stable, firm and glued.

It offers two groups of the upper and lower gluing tanks, which is adopted with automatic adjusting vertically in gluing tank, and teeth rods for adjusting horizontally, for easy operation.

It is adopted with touch screen, PLC controller, photoelectric counting, automatic sheet kicker.

Conveyer part is equipped with sponge belt, ensuring product counting, transversely receiving the paper box.

The machine is able to 2-folding, 4-foiding with bottom gluing. In the per-folding part, the first fold and the third fold can be exchanged by 180 degree or 90 degree. The second fold and the fourth fold can be molded in 180 degree; the special design is also available.

It is adopted with Japanese (NIAT) belts.

|

|

|

|

|

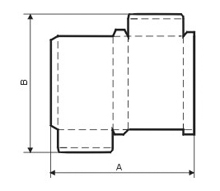

Straight line (mm) |

|

A MAX |

1380 |

|

A MIN |

160 |

|

B MAX |

850 |

|

B MIN |

200 | |

|

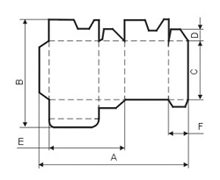

Crash-Lockbotombox (mm) |

|

A MAX |

1300 |

|

A MIN |

260 |

|

B MAX |

1250 |

|

C MIN |

150 |

|

D MIN |

50 |

|

E MIN |

125 |

|

F MIN |

50 | |

|

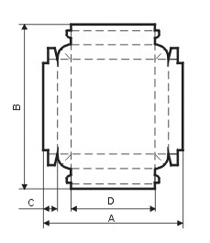

Double size(mm) |

|

A MAX |

1380 |

|

B MAX |

1250 |

|

C MAX |

20 | |

|

Main Specification |

|

Max speed |

200 m/min |

|

Required power |

17.2kw |

|

Dimension(LXWXH) |

13×1.6×1.8m |

|

Gross weight |

7 T | |